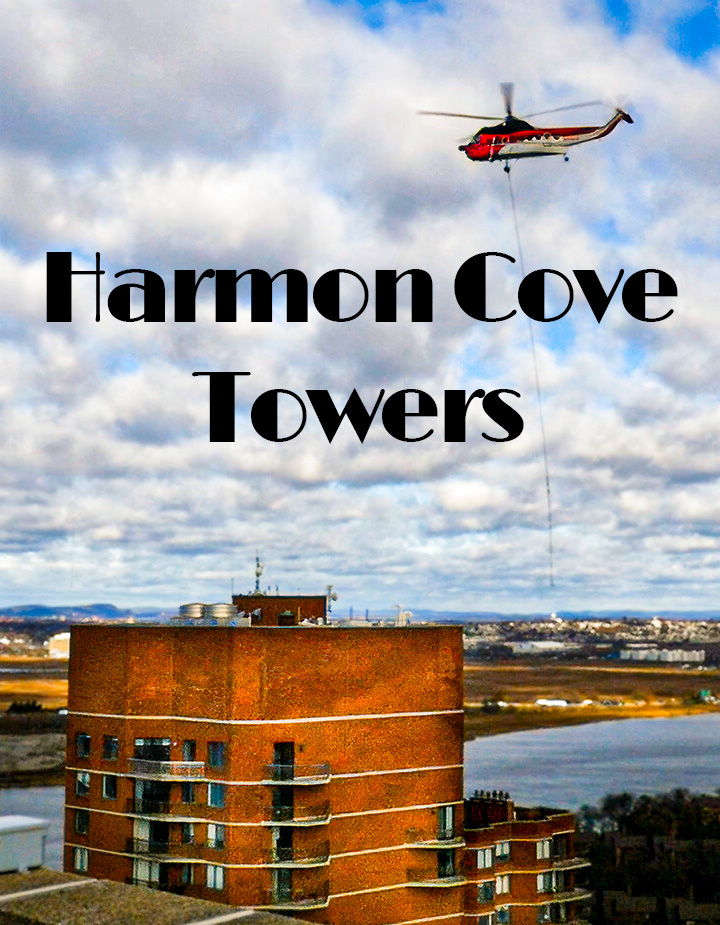

Harmon Cove Towers Harmon Cove Towers

Cooling units replaced on twin rooftops

Replacing rooftop cooling systems on top of high-rise residential buildings that require specialized construction helicopters is not in the wheelhouse of just any North Jersey mechanical company. It’s a very sophisticated operation that requires months of detailed planning, prefabrication, demolition, removal and site preparation before a single new cooling tower can be put in place.

Because Evco Mechanical had successfully completed a similar operation earlier that spring in Cliffside Park, they were perfectly suited to handle the Harmon Cove project, as you’ll see in the video.

The first major phase at Harmon Cove was the removal of a dozen 40-year-old cooling towers, 6 on one roof and 6 on the other, which had deteriorated to the point of no return. The steel frames beneath the old towers, as well as the cooling towers, had to be cut into pieces small enough to fit into the service elevator. The operation began in August and it took about 3 months for tons of heavy scrap steel to be brought down the elevators daily, loaded into containers and hauled away.

Meanwhile, Evco was fabricating new structural frames back at its headquarters to support the new towers, which were lighter and with a smaller footprint than the previous towers. Once the roofs were cleared, the next phase was hauling pre-fabricated steel up the elevators and then assembling the frames, which took a month.

When the towers were delivered and were originally placed on the community tennis courts. Three days prior to the helicopter operation, Evco brought in a 220-ton crane to lift each tower to a staging area on top of the parking deck which was much closer to the main buildings. Because of the units’ weight, they had to be strategically placed on the deck’s support columns to preserve the integrity of that structure.

Helicopter Day

When everyone arrived at Harmon Cove at 6 am on the big day in November, it was a lot colder and windier than everyone had hoped. But after a safety flyover and wind test by the helicopter pilot, the job was greenlit. Sustained winds of 25mph, with gusts up to 40mph, were not enough to stop the operation. The helicopter pilot was a real pro.

At 9 am sharp, the helicopter returned, and the 12 units were ready to be lifted to the twin roofs and lowered into place. Although the original estimate was 3 hours to completion, the operation was done in 2 hours and 44 minutes … and things couldn’t have gone any smoother.

The entire project, aimed at minimizing inconvenience to the residents, was a success and they now have 12 new, fully stainless steel cooling towers to provide them with reliable air conditioning for many, many years to come.